Where Quality

Meets Scale

Inside our 75,000 sq. ft. sustainable manufacturing hub. We combine traditional craftsmanship with modern precision to deliver over 1 million eco-friendly bags monthly.

Facility Area

Stitching Machines

Bags Monthly

Skilled Artisans

The Process

Manufacturing Journey

Raw Material Sourcing

We procure Premium Grade-A golden jute directly from sustainable farms in the Bengal delta.

Dyeing & Lamination

Eco-friendly water-based dyes and food-grade lamination ensure safety and vibrant colors.

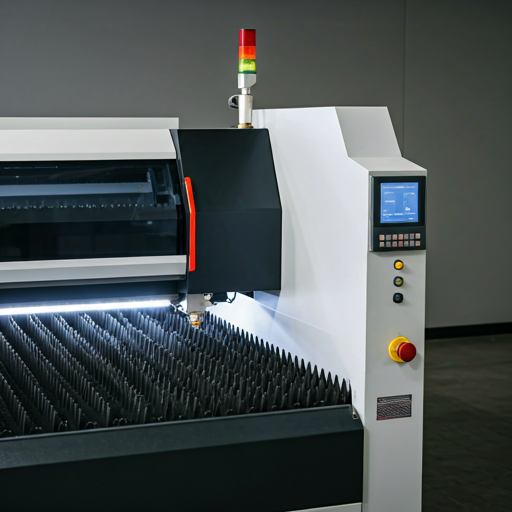

Precision Cutting

Computerized cutting tables ensure 100% accuracy and minimal fabric wastage.

Screen Printing

High-definition prints using AZO-free inks for sharp, lasting branding.

Stitching & Finishing

Double-stitch reinforcement and rigorous quality checks before packing.

Our Capabilities

Production & Branding

Comprehensive facilities to handle diverse product types including Jute, Cotton, Canvas, Juco, and other natural fabrics.

Printing Facilities

- check_circle12 x 100 Ft. Screen Printing Tables

- check_circleHeat Transfer Printing

- check_circleDigital Printing Provision

Branding Options

- check_circleCustom Embroidery

- check_circleCustom Printed Tags

- check_circleCustom Printed Boxes & SKUs

Product Types

- check_circleJute & Juco Bags

- check_circleCotton & Canvas Bags

- check_circleUtility Merchandise

Our 3-stage QC process ensures 99.9% acceptance rate.

Quality Assurance

Precision in Every Stitch.

Quality isn't just a checkpoint; it's our culture. From the tensile strength of the jute fiber to the durability of the final stitch, every OM International bag undergoes rigorous testing to meet global export standards.

Lab Tested Materials

All raw materials are tested for strength, color fastness, and eco-compliance.

In-Line Inspection

Continuous monitoring during cutting, printing, and stitching phases.

Pre-Shipment Audit

Final random sampling based on AQL 2.5 standards before dispatch.